Perlon® will also be represented by two experts at the Global Fiber Congress in Dornbirn from 14th to 16th September 2022. Focus topics include Fiber Innovations und Sustainability, Circular Economy & Recycling which will also be covered by our speakers. Conferences like this offer a lively exchange between international experts from academic research and industry.

Lecture by Christian Fleschhut,

15th September at 4:00 p.m. Hall B.

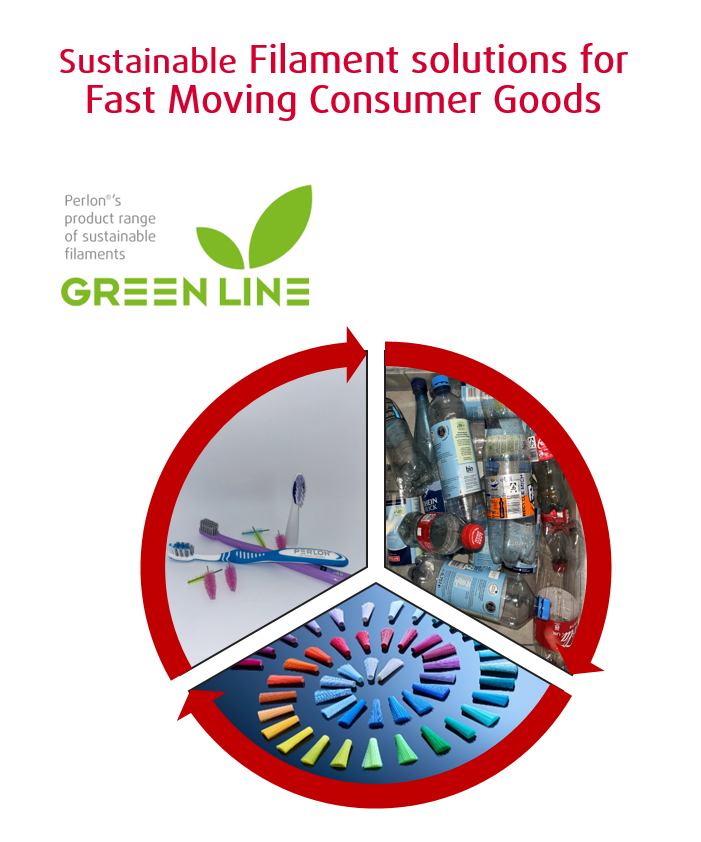

About Sustainable filament solutions for fast moving consumer goods.

Sustainable filament solutions for fast moving consumer goods Sustainability is particularly important for everyday items such as cosmetic brushes or tooth brushes. As pioneer and market leader for sustainable bristles, Perlon® developed and introduced the „GreenLine Filaments“ range more than a decade ago to the market. The product range is steadily extended and is an important part of Perlon®’s commitment and activities for environmental preservation and to reach its climate goals. This presentation shows the latest developments and the impact of the GreenLine product range on the CFP compared to the standard polymers made of crude oil.

Lecture by Dr. rer. nat. Benedikt Neugirg,

16th September at 11:00 a.m. Hall A.

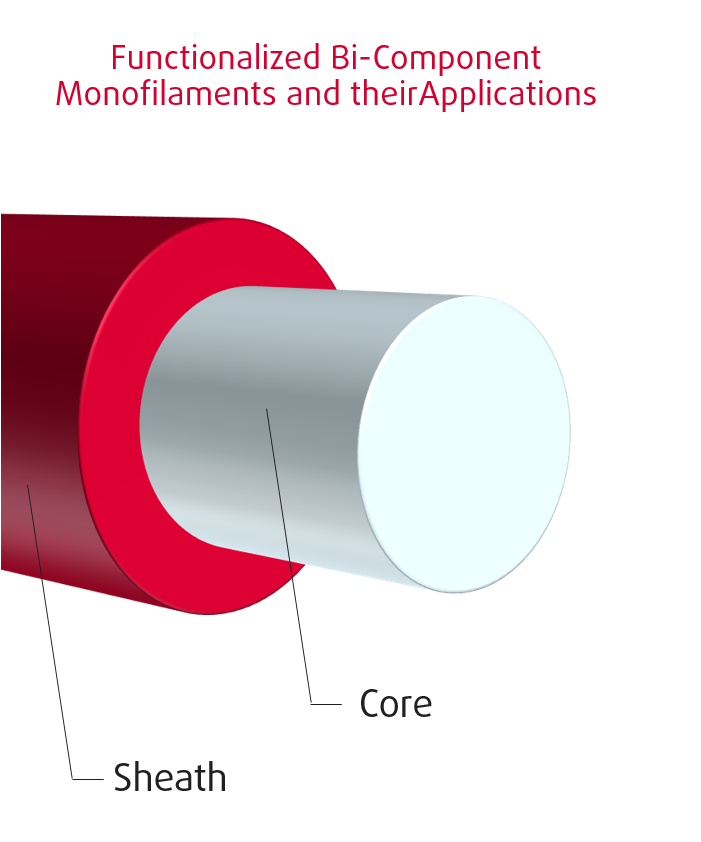

Functionalized Bi-Component Monofilaments and their Applications.

As the demand for specific performance and functionalized monofilaments is growing, co-extrusion provides a versatile technology which enables to combine the properties of different polymers. The mechanical properties like tensile modulus, strength or elasticity are mainly determined by the nature and diameter of the core while the sheath polymer is selected to provide a specific functionalization of the surface.

The intrinsic functionalization of the surface is in many cases a sustainable and environmental friendly alternative to post-production treatment like coating applied in technical fabrics.

Perlon® group offers a wide range of bi-components monofilaments made of two different polymers which are co-extruded into one single fibre. The two components are selected to achieve a customized combination of properties designed for a specific application. As both polymers are combined in a molten state, an outstanding adhesion core/sheath can be achieved. The percentages of core and sheath can be modified according to the desired end properties.

This lecture will present our versatile portfolio of bi-component monofilaments and their application. Example of synergetic effects will also be highlighted. Among others, following products will be reviewed: Wear Indicator, AntiStat, HighGrip, BicoFusible

zurück