A warm welcome to Perlon® – The Filament Company. We are an innovative, global group of companies specialized in the manufacture of synthetic filaments in diverse areas of application.

Our factories in Germany, Poland, China, India and USA produce filaments for applications in the paper machine industry (PMC), the brush industry and for technical textiles as well as filaments for cosmetic and dental applications.

Perlon® looks back with pride at a long tradition in filament manufacture and also formulates from this its claim to be the innovation leader in this highly specialized technological area.

The comprehensive product portfolio is based on a variety of raw materials. In line with the intended application, these are modified and processed into high quality, application-specific filaments. The consistent high quality of our products sets worldwide benchmarks.

Our Engineering. Your success.

We are the biggest global filament producer with global production and global product availability. We produce high quality products in a wide product portfolio with focus on innovation as well as sustainability and recycling products. We serve our customers with focal point on fast, clear and honest communication.

Perlon® has a competent international team of experts in different areas with strengths in product innovations, product development and problem solving. We are a reliable, flexible and customer-focused partner with a strong market and product knowledge.

History

There are not many names which – like Perlon® – are so closely connected with the history of German industry and have acquired such positive prominence. Since 2016 the name has stood for the joint company group of PerlonNextrusion and Hahl-Pedex – the globally positioned Perlon® Group. Almost 100 years of experience in filament manufacturing flows through the company. The enormous technical expertise is strongly shaped by the core competences of the individual locations.

The four centres in Bobingen, Dormagen, Munderkingen and Wald-Michelbach have bundled together their know-how and thus created a unique overall portfolio with the areas PMC & ATT monofilaments, brush & abrasive filaments as well as dental & personal care filaments. A powerful company has developed from this which is in the position to supply customers worldwide with innovative high-tech filaments for virtually any end application: Perlon GmbH – The Filament Company.

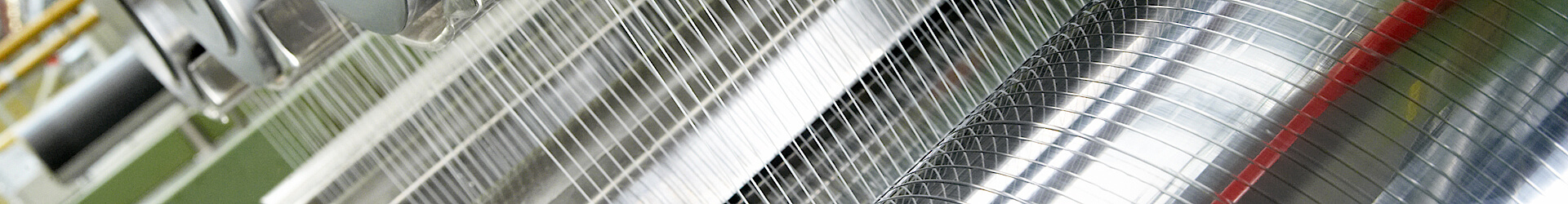

Center of excellence for Paper Machine Clothing (PMC) and Advanced Technical Textiles (ATT)

- 1946 Start of Polyamid Perlon® Monofilament production for bristles under Works Director Prof. Paul Schlack

- 1956 Start of Polyester Trevira® Monofilament production under property of Hoechst AG

- 1972 Development of hydrolytic stabilized polyester monofilaments for PMC dryer fabrics based on own patents

- 1985 Introduction of high speed process for polyester monofilaments for PMC forming fabrics with superior diameter uniformity and equal running length spools on automated winder

- 1987 Development of inline diameter control laser scanner for 100% controlled monofilaments

- 1998 Installation of first co-extrusion line for bicomponent filaments

- 2000 Fully computerized integration of plant and process control for 100% retraceability of process and product data

- 2001 Development of ultrahigh speed process for very fine diameter monofilaments down to 64 micron on cops

- 2014 Perlon-Monofil and Nextrusion, the two world-beating German monofilament manufacturers, pool resources and merge to form the PerlonNextrusion Group

- 2015 PerlonNextrusion and Hahl Pedex merge together under the Serafin Unternehmensgruppe to form Perlon® – The Filament Company

- 2020 Site expansion by installation and commissioning of several extrusion lines from Dormagen site, particularly for Bayco® wire and fishing lines

Main Expertise in Polyamide Monofilaments

- 1949 Start of Monofilament production under property of Bayer AG

- 1949 The first hundred tonnes of Perlon® monofilament roll off the production line in Dormagen – as fishing lines and bristles

- 1972 Development of hydrolytic stabilized polyester monofilaments for PMC dryer fabrics based on own patents

- 1958 New Building F18

- 1968 Launch PA6 for Press felts

- 2008 New production line with fully automated winder

- 2014 Perlon-Monofil and Nextrusion, the two world-beating German monofilament manufacturers, pool resources and merge to form the PerlonNextrusion Group

- 2015 PerlonNextrusion and Hahl Pedex merge together under the Serafin Unternehmensgruppe to form Perlon® – The Filament Company

- 2020 Strategic shift of all production lines to other sites of the Perlon® Group and opening of Perlon® Sales Office Dormagen

Main Expertise in Abrasive and Synthetic Brush Filaments

- 1923 Foundation of Hahl Filaments a finisher and dresser of natural fibres for the brush industry

- 1950 Start of production of cut synthetic filaments

- 1970 Production of continuous monofilament

- 1993 Foundation of Recytec and construction of a fully automated, purpose-built warehouse

- 2000 Abrasive filament manufacture starts

- 2011 Hahl Filaments, Hahl Inc. and Pedex merge to form the Hahl-Pedex Group

- 2015 PerlonNextrusion and Hahl Pedex merge together under the Serafin Unternehmensgruppe to form Perlon® – The Filament Company

- 2020 Capacity expansion by takeover from Dormagen extrusion lines for PMC Monofilaments

Center of excellence for Dental & Personal Care and 3D printing filaments

- 1967 Foundation of Pedex a component supplier for the shoe industry

- 1975 Start of Filament production

- 1982 Filament innovations based on co-extrusion technology

- 2002 Installation of two additional co-extrusion lines

- 2011 Hahl Filaments, Hahl Inc. and Pedex merge to form the Hahl-Pedex Group

- 2013 Start of 3D printing filament production

- 2015 PerlonNextrusion and Hahl Pedex merge together under the Serafin Unternehmensgruppe to form Perlon® – The Filament Company

- 2019 Investment in another coextrusion line and in a robotassisted comb machine for long hanks

Local supplier for USA & Canada

- 1982 Start of Monofilament production under property of Glassmaster

- 1988 Product line of Abrasive filaments has been established

- 2011 Hahl Filaments, Hahl Inc. and Pedex merge to form the Hahl-Pedex Group

- 2011 Set up production lines for Synthetic Brush and Monofilaments

- 2015 PerlonNextrusion and Hahl Pedex merge together under the Serafin Unternehmensgruppe to form Perlon® – The Filament Company

- 2019 Strategic site expansion by installation and commissioning of the first PMC monofilament line to supply local customers

Local supplier for the Chinese PMC market

- 2016 Foundation of Perlon China and start of Monofilament production

- 2018 Construction of new facility, relocation of existing production lines and installation of new filament line

- 2019 Capacity expansion by takeover from Dormagen extrusion lines for PMC Monofilaments and opening of Perlon® Sales Office Shanghai

- 1995 Foundation of Nowo Products as a service provider for fishing line production for Bayer Faser

- 1998 Purchase of the first twisting machines and expansion of the product range with twisted filament

- 2001 Strategic investment in several twisting machines lead twisting to the core business

- 2002 Extension of the product portfolio with termofixed twisted yarns

- 2016 Foundation of Nowo Bis as a service provider for candle wick production

- 2018 Cooperation with the Perlon® Group begins

- 2022 Takeover of Nowo Products and Nowo Bis by Perlon GmbH

- 2001 Shaun Filaments was established by Mr. Sudin Naik and Mrs. Vinata Naik in Kakoda Industrial Estate to manufacture monofilaments.

- 2002 Shifted operations to Verna Industrial Estate.

- 2006 Acquired second extrusion lines from Reimotec GmbH to start manufacturing other types of monofilaments for ATT and other industrial applications.

- 2018 Shaun Filaments was the largest producer of embroidery monofilament yarns for the Indian market with production of around 80 to 90 tonnes per month.

- 2023 Acquisition of Shaun Filaments by Perlon GmbH & Serafin Group through their new company in India called Perlon Goa Private Limited.

Production sites

- Employees: 285

- Turnover in € million: 64

- Breakdown of sales: 78% PMC-Monofil, 22% ATT-Monofil

- Employees: 214

- Turnover in € million: 29

- Breakdown of sales: 33% Synthetic Brush Filament, 33% Abrasive Filament, 20% ATT-Monofil, 12% PMC-Monofil, 2% Recytec

- Employees: 152

- Turnover in € million: 21

- Breakdown of sales: 72% Dental & Personal Care Filament, 21% Synthetic Brush Filament, 7% ATT-Monofil

- Employees: 82

- Turnover in € million: 16

- Breakdown of sales: 33% ATT-Monofil, 24% Synthetic Brush Filament, 15% Abrasive Filament, 28% PMC-Monofil

- Employees: 106

- Turnover in € million: 12

- Breakdown of sales: 100% PMC-Monofil

- Employees: 40

- Turnover in € million: 1,4

- Breakdown of sales: 79% PMC-Monofil, 21% ATT-Monofil

- Employees: 59

- Turnover in € million: 0,36

- Breakdown of sales: 96% ATT-Monofil, 4% Synthetic Brush Filament

Serafin

Perlon® is a part of Serafin Group, whose philosophy is based on more than 150 years of entrepreneurial tradition of its shareholding family. Serafin invests into companies with the aim to foster their long term development in accordance with all stakeholders.

Management Team

Kamil Grzelak

Managing Director / Co-CEO

Matthias Peter

Managing Director / Co-CEO

Michael Holzmann

Managing Director / CFO

Lena Haubrich

Chief Sales Officer / CSO

Andreas Fischer

Chief Technical Officer / CTO

Frank Winkes

Vice President Business Segment PMC

Systematic quality

Customer satisfaction is paramount at the Perlon® Group. We are fully committed to constantly improving the quality of our products. We observe strict compliance with the ISO 9001:2015 standard for quality management systems. All members of staff are actively involved in the continuous improvement process.

Our management system is subject to regular internal and external audits, and ensuing recommendations are implemented. Our business objectives are guided by our high quality standards. In this way, we achieve optimum control of the indicator-based processes and establish a highly efficient management system. The result is top quality – Made in all Perlon® facilities.

Environment

occupational safety and energy efficiency

Environmental protection, occupational safety and energy efficiency stand alongside quality, productivity and cost-consciousness as the main pillars of our corporate philosophy. We are continuously mindful of our duty to adhere to the standards for environmental and energy management systems and therefore follow the guidelines of ISO 14001 and are ISO 50001 compliant. Our robust policy on environmental protection and occupational safety is important for the long-term success of the company and for the retention of customer trust.

One of our key objectives in environmental protection is to reduce our ecological footprint. As a matter of course, we comply with environmental legislation, and in our research and development work, we place great emphasis on the sparing use of raw materials and energy resources.

By continuously optimizing our processes and carefully selecting the materials used in product development, we are contributing to a reduction in energy consumption, emissions, sewage and waste.

Enhanced occupational safety also contributes to a reduced environmental impact while improving product safety. The active participation of all employees in our occupational safety processes is explicitly encouraged. In this way, we ensure optimum efficiency and functionality as well as the minimisation of accidents and errors in the workplace.

Perlon®: Safely successful!

Memberships + Cooperations

ABMA – American Brush Manufacturers Association

FEIBP – European Brushware Federation

Verband der Deutschen Pinsel- und Bürstenhersteller e.V.

h_da UNIVERSITY OF APPLIED SCIENCES

fb mk FACULTY MECHANICAL ENGINEERING AND POLYMER TECHNOLOGY

Cooperation partner KIng – Cooperative engineering degree – Bachelor and Master

Our responsibility for human rights and the environment

The Perlon® Group is committed to making a positive contribution to society and the environment besides its economic success. In accordance with the Supply Chain Due Diligence Act (LkSG), we continuously improve our business practices to ensure compliance with human rights and environmental standards in our own business and throughout the supply chain. Our human rights strategy reflects our commitment to ethical conduct as well as transparency and includes the proactive identification and minimization of risks. In order to fulfill our obligations under the LkSG and to put our values into practice, we have taken comprehensive measures to give external stakeholders the opportunity to participate.

Introduction of an online tool for the complaints procedure according to the LkSG. In line with our commitment to continuous improvement and acting responsibly, we have set up an online tool for a complaints procedure. This tool provides a secure and confidential platform where all Perlon® Group stakeholders can report potential violations of human rights and environmental standards. Incoming complaints are processed by a trained case handler and are monitored by the Serafin Group’s Human Rights Responsible. We encourage anyone who has concerns or observes irregularities to report them via our whistleblower tool. Your voice is critical to maintaining our corporate integrity and putting our values into action.

You can submit a corresponding report via the following link: