Sustainability

Perlon® has committed to a sustainable future by addressing our environmental, social and economic drivers and working with partners along our supply chain. In line with our global sustainability strategy, we are focussing on developing closed loop opportunities, reducing CO2 emissions, carefully

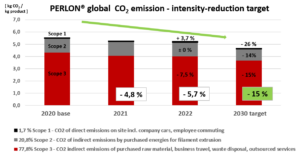

managing our natural resources and implementing responsible sourcing and supplier partnerships. Perlon has set itself the target of reducing the total CO2 emissions of its products by 15 % by 2030, including the emissions burnt in its primary products and purchased energy.

Our target –

Perlon has set itself the target of reducing the total CO2 emissions of its products by 15 % by 2030, including the emissions burnt in its primary products and purchased energy.

Through the continuous optimisation of our processes and the careful selection of raw materials in product development, we are contributing to the reduction of energy consumption, emissions, waste water and waste generation. We are constantly ensuring strict compliance in accordance with the standards

for environmental and energy management systems in line with ISO 14001 and ISO 50001. Recycling is a top priority at Perlon®. We have our own company for this purpose, RECYTEC. Here, unmixed plastic waste can be processed and fed back into the material cycle in various ways.

The UN sustainability goals- –

Part of the Perlon® corporate strategy

At the Perlon® we respect the 17 sustainability goals of the UN and take it as a guideline to formulate our corporate strategy and pursue sustainability goals.

Environment

occupational safety and energy efficiency

Environmental protection, occupational safety and energy efficiency stand alongside quality, productivity and cost-consciousness as the main pillars of our corporate philosophy. We are continuously mindful of our duty to adhere to the standards for environmental and energy management systems and therefore follow the guidelines of ISO 14001 and are ISO 50001 compliant. Our robust policy on environmental protection and occupational safety is important for the long-term success of the company and for the retention of customer trust.

One of our key objectives in environmental protection is to reduce our ecological footprint. As a matter of course, we comply with environmental legislation, and in our research and development work, we place great emphasis on the sparing use of raw materials and energy resources.

By continuously optimizing our processes and carefully selecting the materials used in product development, we are contributing to a reduction in energy consumption, emissions, sewage and waste.

Enhanced occupational safety also contributes to a reduced environmental impact while improving product safety. The active participation of all employees in our occupational safety processes is explicitly encouraged. In this way, we ensure optimum efficiency and functionality as well as the minimisation of accidents and errors in the workplace.

Perlon®: Safely successful!

The GreenLine product range

The Perlon® range of sustainable filaments

„Regranulate“

Circular economy/circular raw material, mechanical/thermal recycling

• Quality in line with specifications

• Optimally sustainable

• Meets legal recycling quota requirements

„Sustainability line“

Circular economy/circular raw material, chem. recycling, depolymerization

• Identical material compared to Virgin, FDA

• Meets legal recycling quota requirements

„Bio based“

Climate protection/renewable raw material

• Bio based e.g. from bio ethanol, sebacic acid, tall oil etc.

„Bio degradable”

Waste management/biodegradable raw material

„Low carbon”

Climate protection/CO2 reduction

• Use of green energy

• Suppliers or raw materials with low carbon footprint

• Up to 100 % CO2 compensation